What are Ceramics?

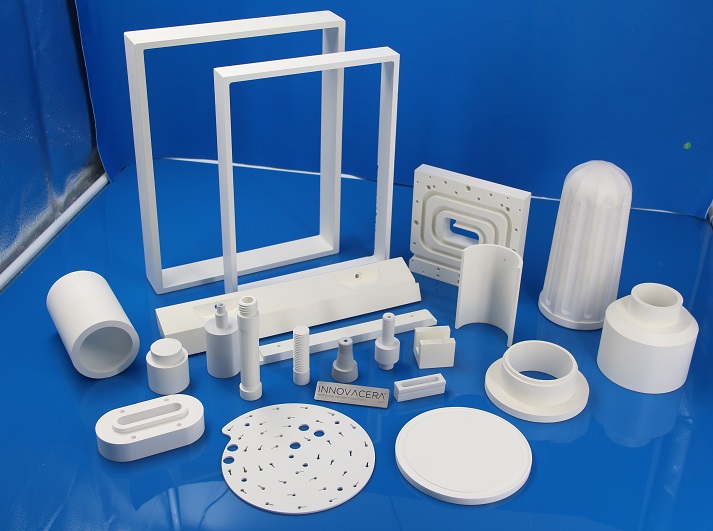

Ceramics encompass such a vast array of materials that a concise definition is almost impossible. However, one workable definition of ceramics is a refractory, inorganic, and nonmetallic material. Ceramics can be divided into two classes: traditional ceramics and advanced ceramics.

Traditional ceramics include clay products, silicate glass and cement

Advanced ceramics consist of carbides (SiC), pure oxides (Al2O3), nitrides (Si3N4), non-silicate glasses and many others.

In general, advanced ceramics have the following inherent properties:

- Hard (wear resistant)

- Resistant to plastic deformation

- Resistant to high temperatures

- Good corrosion resistance

- Low thermal conductivity

- Low electrical conductivity

However, some ceramics exhibit high thermal conductivity and/or high electrical conductivity.

The combination of these properties means that ceramics can provide:

- High wear resistance with low density

- Wear resistance in corrosive environments

- Corrosion resistance at high temperatures

Ceramics offer many advantages compared to other materials. They are harder and stiffer than steel; more heat and corrosion resistant than metals or polymers; less dense than most metals and their alloys; and their raw materials are both plentiful and inexpensive. Ceramic materials display a wide range of properties which facilitate their use in many different product areas.

- Aerospace: space shuttle tiles, thermal barriers, high temperature glass windows, fuel cells

- Consumer Uses: glassware, windows, pottery, Corning¨ ware, magnets, dinnerware, ceramic tiles, lenses, home electronics, microwave transducers

- Automotive: catalytic converters, ceramic filters, airbag sensors, ceramic rotors, valves, spark plugs, pressure sensors, thermistors, vibration sensors, oxygen sensors, safety glass windshields, piston rings

- Medical (Bioceramics): orthopedic joint replacement, prosthesis, dental restoration, bone implants

- Military: structural components for ground, air and naval vehicles, missiles, sensors

- Computers: insulators, resistors, superconductors, capacitors, ferroelectric components, microelectronic packaging

- Other Industries: bricks, cement, membranes and filters, lab equipment

- Communications: fiber optic/laser communications, TV and radio components, microphones