Aluminium nitride has a high heat transfer ability so that aluminium nitride is widely used in microelectronics. Unlike beryllium oxide, aluminium nitride is non-toxic. Aluminium nitride is treated with metal and can replace alumina and beryllium oxide for a large number of electronic instruments.

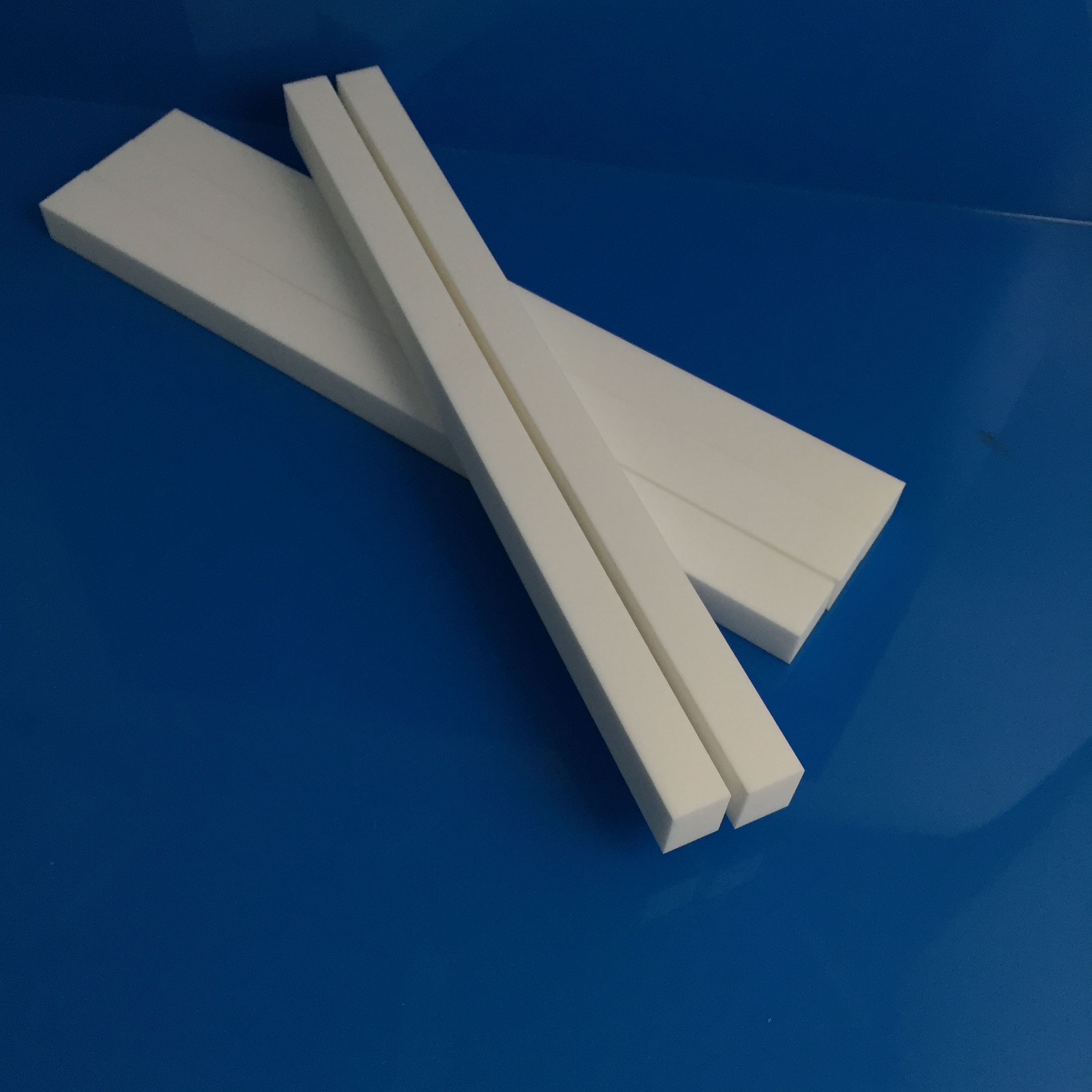

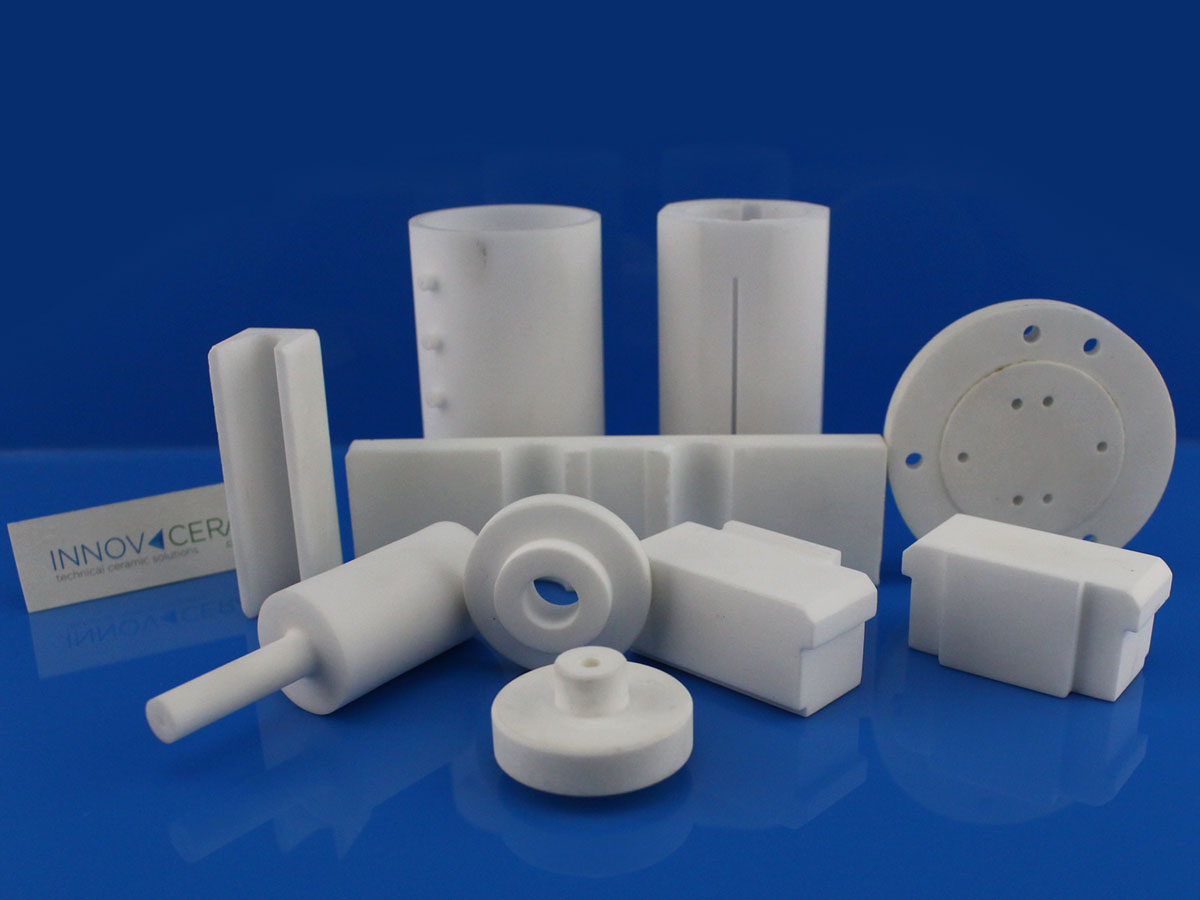

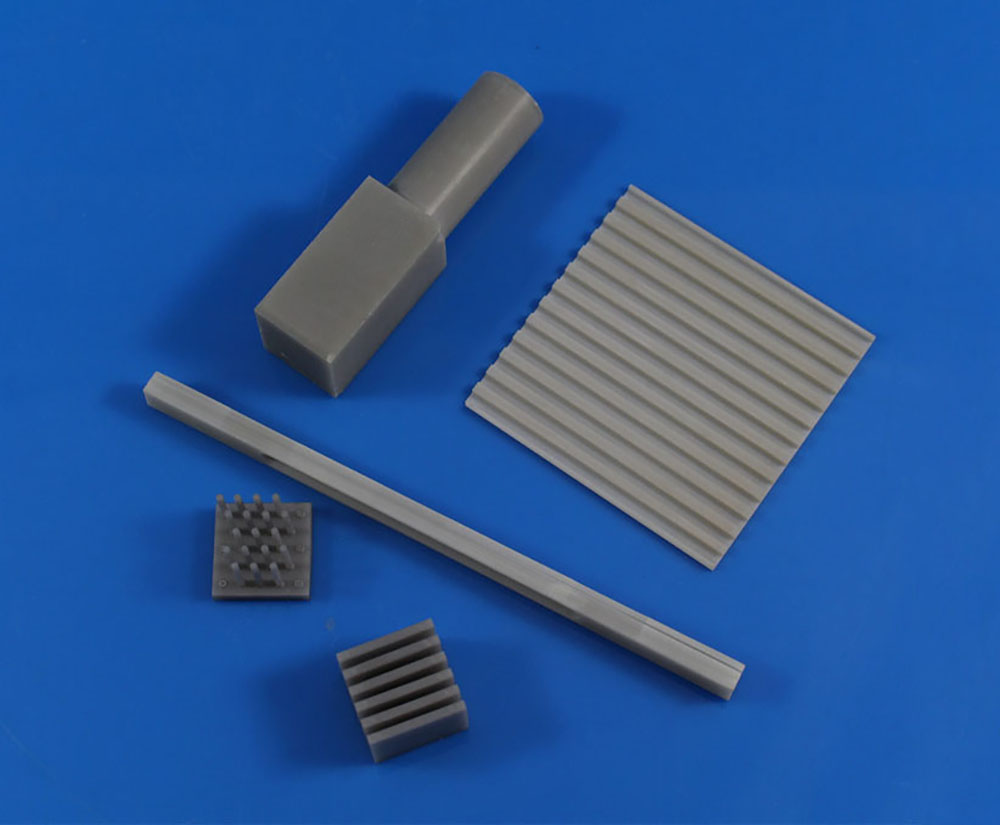

(1) Refractory materials. Aluminium nitride is not only resistant to high temperature, corrosion, alloys and metals such as aluminium and iron, but also non-wetting with silver, copper, aluminium, lead, etc., and can be used to make refractory materials or coatings for crucibles as surface protection material. It can also be made into structural materials such as casting moulds and crucibles.

(2) Electronic substrate material. Aluminium nitride ceramics are widely used in multi-chip modules in military fields, microwave power amplifiers, and laser diode carriers, LED heat sink substrates and high-temperature semiconductor packages in civilian fields. Aluminium nitride substrates are also widely used in electric and gas hybrid automobiles — aluminium nitride ceramic carrier substrate for power module circuits. The use of aluminium nitride as the LED packaging material has the following advantages: Good heat resistance and thermal conductivity, which can increase the service life of the material; Can make a thinner packaging material.