Innovacera develops many kinds of Zirconia ceramic parts for all kinds of pumps & valves. Such as waterjet zirconia ceramic plunger for severe service and high-pressure systems.

Ceramic pumps and plungers are the ideal replacements for the metal in high pressure, high wear, high temperature, saltwater, chemical, and metering applications.

The waterjet intensifier ceramic plunger for the water jet is used on 60k ultra high-pressure intensifier waterjet pump 50HP, 60HP,100HP, 40KPSI, and 60KPSI.

The max pressure it undertakes can be 60 Kpsi , voltage of 220v/380v.

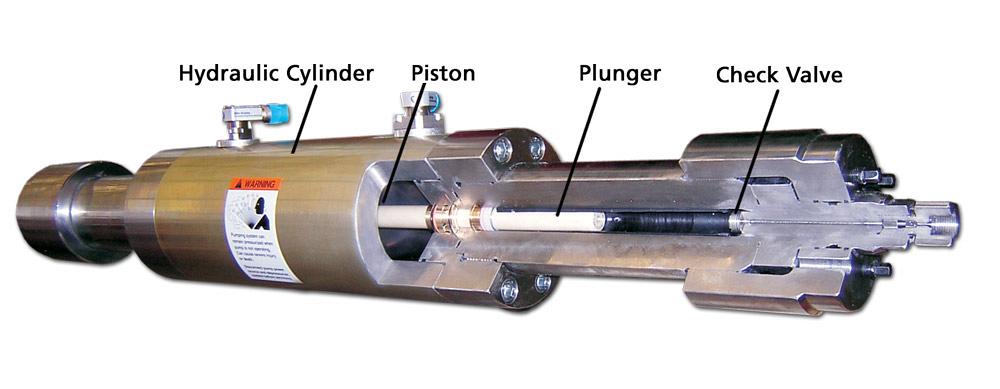

The ceramic connects with the metal cap by heat shrinkage, it is the strongest assembling ceramic to metal, and not easy to fall apart. The surface of the zirconia rod is mirror polished, with fine surface roughness, so it is wear-resistant and can work for a long time. And zirconia ceramic material with good toughness and fracture strength. Below is the waterjet cutter machine intensifier pump structure with a zirconia ceramic plunger for reference:

Zirconia Ceramic Material Properties:

| Zirconia Ceramic Material Properties | |||

| Technical Parameter | Technical Item | Unit | Value |

| Physical Properties | Major content | % | ZrO2+HfO2: 94.65%, Y2O3: 5.35% |

| Density | g/cm3 | ≥6.0 | |

| Water absorption | % | 0.00 | |

| Mechanical Properties | Hardness | HV | 1,400.00 |

| Bending Strength | Kgf/mm2 | 11.00 | |

| Compressive Strength | Kgf/mm2 | 25.00 | |

| Temperature Properties | Thermal Expansion Coefficient (0-1000℃) | (10-6/K) | 9.5*10-6 |

| Thermal Shock Resistance | T(℃) | 360.00 | |

| Thermal Conductivity | W/m.k | 3.00 | |

| Volume Resistance Rate (20℃) |

(Ω·cm) | >10 12 | |

| Remark: The value is just for review, different using conditions will have a little difference. | |||

|

Innovacera Waterjet Zirconia Ceramic Plunger Features: Mirror polished Waterjet Zirconia Ceramic Plunger Size Specifications: 22.22*207mm We provide zirconia ceramic plungers for below-water jet cutters equipment:

|

|||