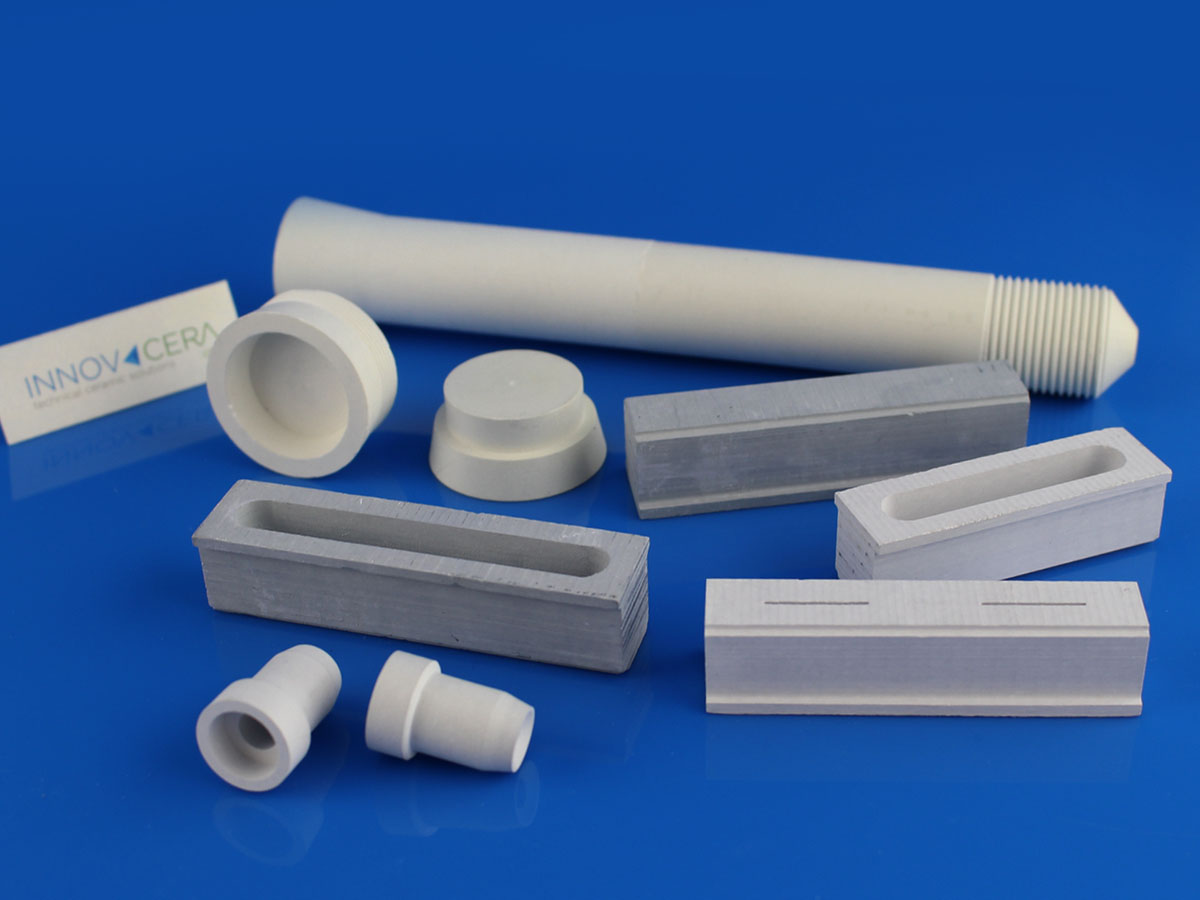

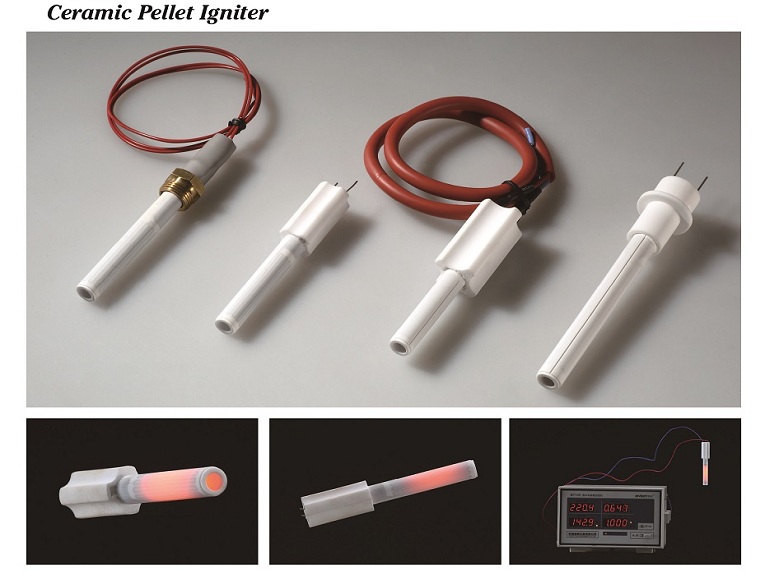

INNOVACERA® Ceramic Igniters Will Keep You Warm In The Coming Winter offers ceramic igniters for hot surface ignition systems in heating applications. These high strengths, heat resistant ceramic igniters have become an industry-standard in gas heating systems. Their superior materials and rapid heating capabilities provide reliable performance over a long useful life.

Applications include:

- Gas heating systems

- Ovens/ranges

- Dryers

- And more

Ceramic ignition technology benefits

- A fraction of the energy consumption compared to conventional cartridge or element heater

- Long-lasting

- Time to ignition 60~90 seconds

- Tested to 100,000 cycles (in Japanese pellet market for 15 years)

- Easy to install and retrofit

- Fits any steel tube with an inner diameter of ≥18mm

- 1000°C at steady-state temperature

- Cannot overheat even with blower failure

- 100/120/220/240V forward current

- Fully electrically insulated with no exposed electric contacts

- Impervious to oxidation and corrosion

- Fully comply with the CE (TUV certification), ROHS and REACH (TUV certification) directives.

- Ignite wood chips, split logs, coal briquettes or other biomass, straw, corn etc.

If you are interested in our ceramic igniter, please click here to contact us, or you can buy it directly at our store: https://www.innovamats.com/product-tag/alumina-ceramic-igniter/