Lanthanum hexaboride (LaB6) also called lanthanum boride, and LaB6 is an inorganic chemical, a boride of lanthanum. It is a refractory ceramic material with a dark purple appearance that has a melting point of 2210°C, and is insoluble in water and hydrochloric acid. When bombarded with ions, its physical appearance is altered, and it has a green color in place of its usual dark purple color.

The unique properties of lanthanum hexaboride crystals provide stable electron-emitting media with work functions near 2.70 eV. The low work function yields higher currents at lower cathode temperatures than tungsten, which means greater brightness, or current at the beam focus, and longer life. Typically, LaB6 cathodes exhibit 10 times the brightness and 50 times the service life of tungsten cathodes. In electron microscope applications, these characteristics translate to more beam current in a smaller spot at the sample, improved resolution, and less frequent cathode replacement.

Lanthanum Hexaboride Applications:

Thermionic emission (cathode)

Plasma source for plasma-enhanced coating(PECVD)

Vacuum electron beam welding machine

Electron beam surface reforming device

Electron beam lithography device

Transmission electron microscope

Scanning electron microscope

Surface analysis device

Radiotherapy devices

Lanthanum Hexaboride Properties:

| Properties | Unit | Lanthanum Hexaboride |

| Purity | % | >99.5 |

| Density | g/cm3 | >4.30 |

| Structure | / | Monocrystalline |

| Vickers hardness | HV | 1065 |

| Shore hardness | HS | HS |

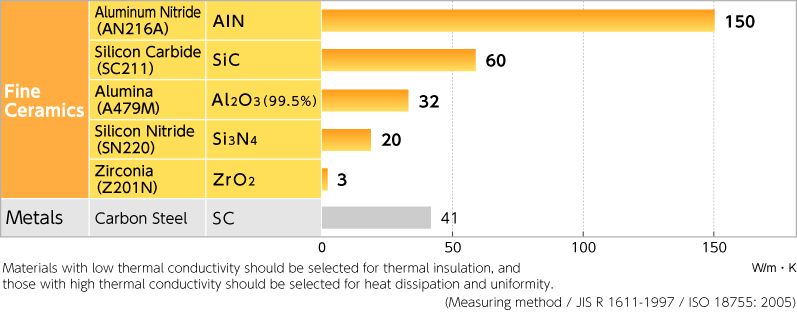

| Thermal conductivity | W/mK | 15 |

| Electrical Conductivity | S/m | 1.83*10^6 |

| Flexural strength | MPa | 165 |

Innovacera supplies our customers with a high-quality Lanthanum Hexaboride ceramic parts.